Hard Soldering Glossary

Talk the talk with these three charts all about the hard soldering jewelry-making technique. The charts below explain the materials used in hard soldering, then the necessary tools to use this skill and finally a list of helpful terms.

For more information about soldering, visit these resources to understand standard soldering terminology, definitions, techniques and tools:

| Soldering Materials | Description |

| Acetylene | A gas used with torches. Acetylene can be used with ambient air, oxygen or compressed air. An acetylene/ambient air combination reaches 3270 degrees Fahrenheit. An acetylene/oxygen combination produces a flame up to 5080 degrees Fahrenheit. An acetylene/compressed air combination reaches 3848 degrees Fahrenheit. This is not a clean burning fuel, so you may find that deposits of blackened carbon are left behind. |

| Anti-Flux | This is quite literally the opposite of flux. Anti-flux is a material that is applied to deliberately dirty a specific area of the metal being soldered. This application keeps solder from flowing to the coated area. Almost anything that is non-flammable and will adhere to your metal can be used as an anti-flux. |

| Binding Wire | Used to hold pieces to be soldered. Binding wire is also wrapped around charcoal blocks to prevent cracking. Use 304 type stainless steel or iron wire in a dead soft temper--this is soft enough to easily manipulate yet can still stand the temperatures used in hard soldering. |

| Butane | The primary fuel used with micro torches. |

|

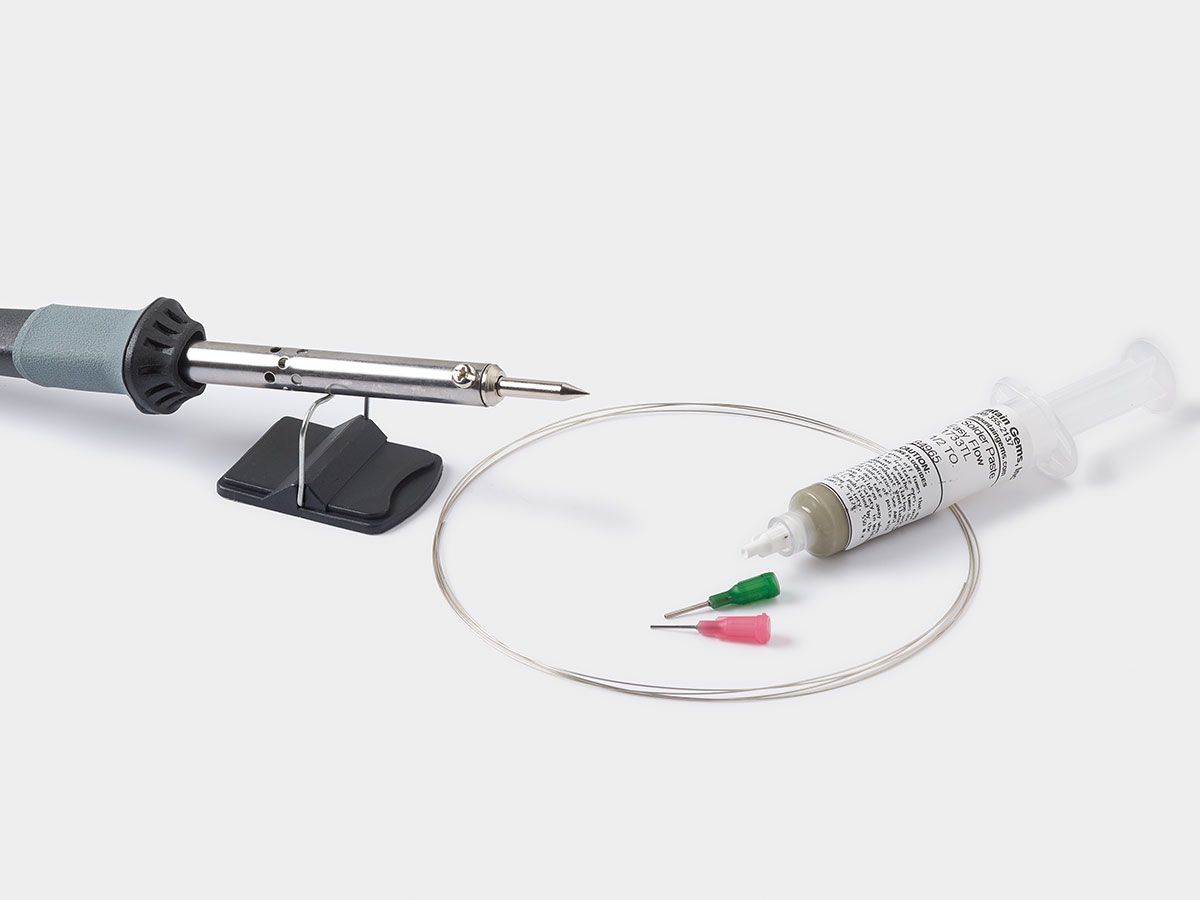

A solution that keeps metal clean, allowing the solder to flow properly. The application of flux also prevents the buildup of oxidation, reducing the chance of firescale and cleanup time. Flux should be applied to both your metal pieces and your solder to ensure no contamination. Flux is available in liquid and paste forms and can be brushed or sprayed onto your pieces. Flux is not usually needed when working with syringe forms of solder, as it has already been added. |

| Natural Gas | A readily available fuel option for torches. Natural gas can be used in tanks with a regulator. Many cities provide natural gas through municipal lines as another supply option; a regulator isn't usually needed in this case. Check for local regulations and hook-up procedures to ensure safety when using a direct gas line. A natural gas/oxygen combination produces a flame up to 5120 degrees Fahrenheit. A natural gas/compressed air combination reaches 3,565 degrees Fahrenheit. Unlike acetylene, natural gas burns clean and does not leave stains from blackened carbon. |

| Oxygen | This is not the "oxygen" that you are currently breathing (which is actually made up of over 10 different gasses, including oxygen). This is pure oxygen that is presented in a pressurized tank. Oxygen is not a fuel, but is used with acetylene and propane in dual tank systems to create hotter flames. As the tank is under pressure a regulator must always be used. |

|

A solution that removes oxides from metal pieces after soldering. Pickle solution works best when warm, but should not be boiling. |

| Propane | This fuel may also be known as LPG (liquefied petroleum gas). Propane can be readily found at hardware and general stores in many areas. In most cases this is a less expensive fuel option for soldering. This fuel can be used with ambient air or with oxygen. |

|

A metal alloy that is specifically formulated to have a lower melting point than precious metals. This is used to join pieces of metal together. Solder is available in wire, sheet and paste forms. There are different grades of solder; each has a different flow point. |

| Soldering Terms and Techniques | Description |

| Applique | Also called overlay. A technique in which a metal piece is soldered to the top of a larger metal piece. |

| Ball | This is what solder does as it reaches the melting point. This indicates that the metal and solder are reaching the flow point. |

Butt Join |

A soldering technique that joins two pieces of metal end to end. This is the most common join used in jewelry soldering and can be used with both flat and curved pieces. |

| Cupric Oxide | A reddish oxide that forms on sterling silver when it is heated. In most cases this can be removed by immersing the object in warm pickle. |

| Cuprous Oxide | More commonly known as firescale. A stain that appears on your metal due to exposure to heat. Unlike cupric oxide this is more difficult to remove; the oxidation actually goes deep into the metal instead of just being on the surface. Most cuprous oxide can be removed by sanding until all the discoloration is gone; however, this may have an effect on the finished piece. Cuprous oxide appears as a dark purplesque color when working with sterling silver. When soldering brass or bronze the stain will appear copper. Cuprous oxide can be prevented, or at least held to a minimum, by using flux and limiting the heat exposure of the metal as much as possible. |

| Ferrous | A material that contains iron. Generally used in reference to metal. |

| Firescale | Scientifically known as cuprous oxide. A stain that appears on your metal due to exposure to heat. Unlike cupric oxide this is more difficult to remove; the oxidation actually goes deep into the metal instead of just being on the surface. Most cuprous oxide can be removed by sanding until all the discoloration is gone; however, this may have an effect on the finished piece. Fire scale appears as a dark purplesque color when working with sterling silver. When soldering brass or bronze the stain will appear copper. Fire scale can be prevented, or at least held to a minimum, by using flux and limiting the heat exposure of the metal as much as possible. |

| Flow Point | The temperature at which solder follows a join. This temperature is usually about 85 to 120 degrees Fahrenheit higher than the melting point of the solder. |

| Grade | A title that indicates the melting and flow points of solder. There are five grades; extra easy, easy, medium, hard, and extra hard (sometimes called IT or intense temperature). |

| Ghost | A term used to describe blobs of solder that flowed outside of the intended join. |

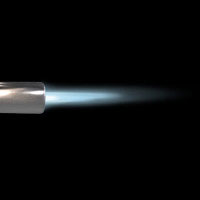

| Hard Soldering | The joining of metals using a molten metal joining agent (solder) and temperatures over 1200 degrees Fahrenheit. The high temperatures needed for this technique are achieved with a torch. |

| Join | The point of connection; this is the area where you want solder to flow and solidify. |

| Melting Point | The temperature at which the solder will ball. This occurs just prior to the flow point of the solder. |

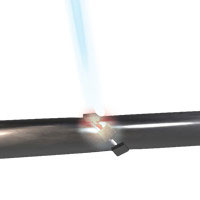

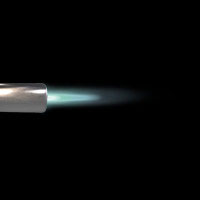

Neutral Flame Neutral Flame |

A neutral flame has equal amounts of fuel and air. You will see a short light blue inner cone with a slightly rounded tip. The outer area of the flame is a darker blue and has a slightly yellow tip. There is no feather shape between the outer envelope and the inner cone. A neutral flame will have a low steady hissing sound. |

| Nonferrous | A material that doesn't contain iron. Generally used in reference to metal. |

| Overlay | Also called applique. A technique in which a metal piece is soldered to the top of a larger metal piece. |

Oxidizing Flame |

An oxidizing flame that has more air than fuel. This type of flame is the hottest and causes oxidation on the metal. The flame has a sharp inner cone and is accompanied by a loud raspy hiss. |

| Pallions | Chips of solder, usually about 1 x 1 millimeter. |

Point of Contact Join |

A soldering technique that joins a small point of contact between two pieces. Considered a difficult technique due to the size difference normally seen between the two metal pieces. |

| Quench | Cooling a soldered piece by immersion in pickle solution. |

Reducing Flame |

A reducing flame has more fuel than air. This type of flame is generally lower in temperature than a neutral flame and helps to ensure less oxidizing on the piece. A reducing flame has a blue cone with a light blue feather around it. The outer envelope of the flame is longer and a brighter blue than on a neutral flame. |

| Self-Pickling | A term used to indicate that a flux will help clean the metal during the application of heat. Items soldered with self-pickling flux still need to be quenched in pickle solution. |

| Soft Soldering | Joining metals together with a melted metal filler (solder generally made with lead and/or tin) at temperatures under 1200 degrees Fahrenheit. This process is most often performed with a soldering iron. |

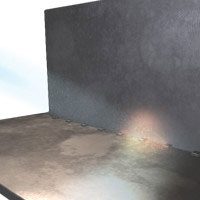

| Solder Station | A fireproof, dust-free, non-cluttered area in which soldering is actually performed. Be sure to put safety and comfort first when putting your solder station together. |

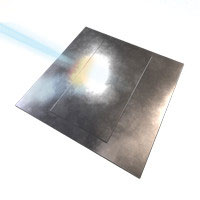

Strip Join |

Also called a T-join. A soldering technique that joins two metal pieces, generally sheets, at a perpendicular angle. The use of a third hand can be quite helpful in this difficult technique. |

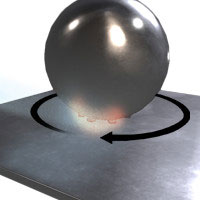

Sweat Join |

A soldering technique that is most often used to solder one sheet of metal to another. In this process, solder flows into the join through capillary action. This process is often considered the easiest technique to master. |

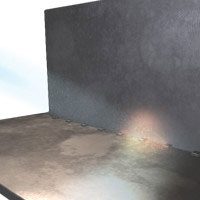

T-Join |

Also called a strip join. A soldering technique that joins metal two pieces, generally sheets, at a perpendicular angle. The use of a third-hand can be quite helpful in this difficult technique. |

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.