How to Use the Eyelet and Rivet Setting Tool

Instructions

Eyelets

For best results, total thickness should not be less than 1/2 the length of the eyelet or rivet.

Note: Rivets and eyelets are 1.9mm, it is necessary to use the left (larger) punch side of item H20-3084TL hole-punch tool as it makes a hole of approximately 2mm.

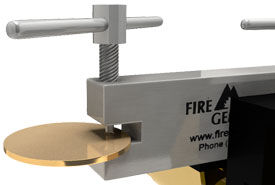

Secure hole-punch tool in bench vise. You will be using the left (larger) punch side of the punch tool.

Insert and align disc to be punched, then turn handle clockwise until hole is fully punched. Turn handle counter clockwise and remove punched disc.

Repeat to punch second disc.

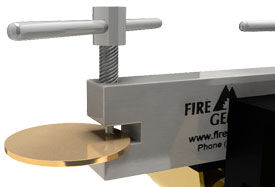

Stack discs with holes aligned and insert eyelet through holes.

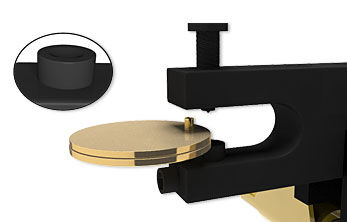

Secure setting tool in bench vise. You will be using the eyelet side (dimpled bottom side) of the setting tool.

Insert eyelet head into the eyelet side (dimpled bottom side) of the setting tool.

Turn hand crank clockwise until tube portion of eyelet is sufficiently flared securing the two discs together.

Turn hand crank counter clockwise and remove attached discs from setting tool.

Rivets

For best results, total thickness should not be less than 1/2 the length of the eyelet or rivet.

Note: Rivets and eyelets are 1.9mm, it is necessary to use the left (larger) punch side of item H20-3084TL hole-punch tool as it makes a hole of approximately 2mm.

Secure hole-punch tool in bench vise. You will be using the left (larger) punch side of the punch tool.

Insert and align disc to be punched, then turn handle clockwise until hole is fully punched. Turn handle counter clockwise and remove punched disc.

Repeat to punch second disc.

Stack discs with holes aligned and insert rivet through holes.

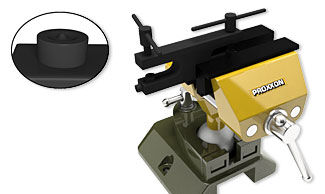

Secure setting tool in bench vise. You will be using the rivet side (bowl-shaped bottom side) of the setting tool.

Insert rivet head into the rivet side (bowl-shaped bottom side) of the setting tool.

Turn hand crank clockwise until tube portion of rivet is sufficiently flared securing the two discs together.

Turn hand crank counter clockwise and remove attached discs from setting tool.

Shop for Your Materials Here:

Have a question regarding this project? Email Customer Service.

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.